Alcohol-free beer still needs improvement in taste. Scott Lafontaine’s research in ACS Food Science & Technology looks at alternative yeasts that can be used to brew tastier beers.

Nowadays, more and more varieties of ‘0.0’ beer are on offer. Consumption of 0.0 is on the rise, reaching 82 million litres of alcohol-free beer in the Netherlands (2022) and 35 million litres in Belgium (2023). At the same time, taste remains a major bottleneck. Many consumers miss the character of regular beer and find alcohol-free variants too sweet or flat in taste. Kevin Verstrepen, professor of microbial and plant genetics at KU Leuven, says there is still a lot of room for improvement in 0.0 beer, but there are alternative yeasts that come close to creating ‘real beer’.

It all has to do with the specifics of the brewing process. ‘In recent years, brewers have learned how to make better non-alcoholic beers,’ says Verstrepen. There are two ways to ensure that the alcohol level stays below the 0.05% by volume limit.

In the first option, the degree of fermentation is minimised right from the start. When you mix the malt with warm water, enzymes are released. These enzymes take care of the production of sugars. This process is called ‘mashing’, and by elevating the temperature, the conversion of sugars into ethanol is limited. The ‘normal’ way of brewing 0.0 beer relies on the removal of the ethanol by vacuum rectification and membrane filtration. The disadvantage of both methods is that you get less complexity in flavour, resulting in a flat-tasting beer.

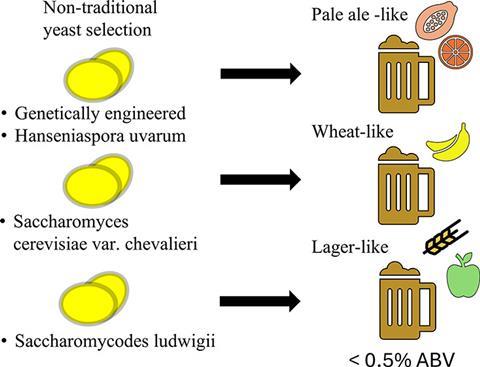

To make 0.0 beers taste better, Scott Lafontaine (University of Arkansas) and colleagues looked at alternative yeasts that can be used in the brewing process, they write in ACS Food Science & Technology. These alternative yeasts offer new opportunities to improve flavour profiles without producing large amounts alcohol. Bioprospecting, hybridisation or genetic modification are other methods to create alternative yeasts for a flavourful 0.0. Research by the Verstrepen-group has already produced some new brewing yeasts, such as the NEER yeast, which doesn’t produce alcohol at all.

What makes alternative yeasts so useful for non-alcoholic beers is that they cannot ferment typical sugars such as maltose and maltotriose, but they can ferment simple sugars such as glucose and fructose. The result is a beer with a yeasty flavour and its own distinct character. Verstrepen: ’It is definitely a good idea to look for new yeasts, especially when it comes to different beer styles, because there are different needs. So, there is growing demand for new alternative yeasts for non-alcoholic beers.’

Several alternative yeast strains are now on the market, with those resulting from hybridisation or genetic modification most closely resembling traditional yeast strains due to their greater precision in the fermentation process. In this way, it is possible to create recipes for 0.0 beers that meet the expectations and desires of consumers. ‘There is still something missing though,’ says Verstrepen, ‘and that is the alcohol itself. Alcohol gives a lot of flavour and aroma and also influences the behaviour of other flavourings. Alcohol also affects mouthfeel and pain receptors.’ Future research will therefore focus on alternatives to alcohol to make non-alcoholic beer even better tasting.

Source:

S. LafontaineACS Food Science & Technology (2025), Exploring non-traditional yeast for flavor innovation in non-alcoholic beers.

Nog geen opmerkingen