The fight against fake medicines stands a better chance if you label the medicine itself rather than the packaging. Think of ‘barcodes’ that manufacturers add to pills and potions, so end users can check with their own eyes that the product is genuine. Soon, something like this may be on the market. Recently, Delft researchers published the blueprints in Advanced Materials Interfaces.

The invention by Burak Eral, assistant professor at TU Delft, and his PhD student Mengmeng Zhang, is to combat counterfeit medicines, which have been a huge problem for years, especially in poor countries. The recent tragedy surrounding poisonous cough medicine in Gambia and Indonesia, among others, which resulted in the death of about 150 children, is almost insignificant compared to the estimate that more than 100,000 people in Africa die unnecessarily every year because they relied on fake malaria medication that is barely effective or not at all. Meanwhile, the World Health Organisation (WHO) also warns of a lively trade in counterfeit corona vaccines.

Reading the code can be done with a simple microscope on a smartphone

Countermeasures have so far focused mainly on labels that are difficult to counterfeit, sometimes in combination with databases of existing batch numbers. But tamper-proof labels are often relatively expensive and not easy to read. And fraudsters have already realised that you can refill an authentic packaging with a fake product after use. Hence, more and more voices are calling for on-dose authentication (ODA), microscopic codes embedded in the medicine itself. The prerequisites are that they should not be harmful to human health, that you should be able to find and check them easily, and that forgery requires more effort than it is worth.

Dot code

In 2017, Eral, together with a group of Utrecht researchers, published an initial draft of such a PES in the journal Small. Through a transparent microfluidic channel, he allowed a liquid to flow that forms crosslinks under the influence of UV light to turn into a hydrogel. Exposure was via stop-flow lithography: the flow was stopped just long enough each time to allow the liquid to harden under the light source. Between light source and liquid was a mask with holes, which acted as a template to create cubes with a dotted code of choice. Reading could be done with a microscope, which can be ordered online for a few dozen euros, and clips onto the camera lens of a smartphone.

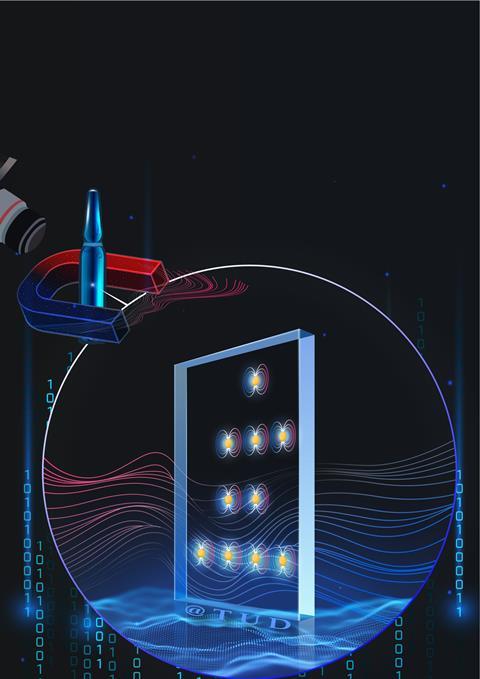

However, it took quite the effort before you had such a cube under the microscope. But Zhang has now found a solution. In the microchannel, she places virtual magnetic moulds (VMMs): thin glass plates on which microscopically small dots of nickel have been deposited in the desired dot pattern. To the liquid, she adds superparamagnetic iron oxide nanoparticles. If you hold a magnet under the channel, iron oxide and nickel are both magnetised and the nanoparticles accumulate around the nickel fragments. Then you let the liquid surrounding it harden, leaving cubes with embedded nanoparticle codes. No doubt there will be methods to read those codes magnetically. But once the cubes are in a medicine bottle, all you have to do is hold a magnet against it to pull them flat against the glass en masse. Armed with the smartphone microscope, you can then write down the code. If the medicine is packed in pills, you will have to randomly dissolve a few to retrieve the codes.

Edible sensors

The current cubes contain 8 by 3 dots, ample for the intended codes. They measure about 0.2 by 0.6 mm, which is small enough to be noticeable only if you know where to look. According to Eral, it is a compromise: ‛The smaller you make them, the harder they are to detect. And the bigger you make them, the easier they are to fake.’ The publication suggests that the latter is mainly complicated by the fact that producing VMMs requires sophisticated precision equipment. Once you have those VMMs, the materials cost a fraction of a cent per cube. Eral and Zhang also assume they are safe for consumption.

In 2017, modified dextran still served as a UV-sensitive polymer but this time they chose PEGDA, polyetheenglycol with acrylate end groups for crosslinking. Unlike the monomer, which ironically seems to have been used in the false cough medicine because it was cheaper than glycerine, this polymer is widely regarded as harmless: its toxicity never seems to have been studied in detail but biomedical labs have long been satisfied with it. Something similar applies to nano-iron oxide. Moreover, Eral argues, the quantities involved are extremely small: ‛Everything is toxic, even water. But it depends on the dosage.’

The publication does suggest that there is still some tinkering to be done before mass production can start. But the authors are already thinking further: instead of barcodes, you could make edible sensors that indicate whether the medicine is still good. The primal version already included a primitive pH indicator, and Zhang’s thesis is not scheduled until next year. Who knows what she might come up with next.

Nog geen opmerkingen