Carbyon is developing a separation machine to extract CO2 from the air. Ultimately, they want to deploy thousands of such machines. ’Our business is successful when we are carbon negative.’

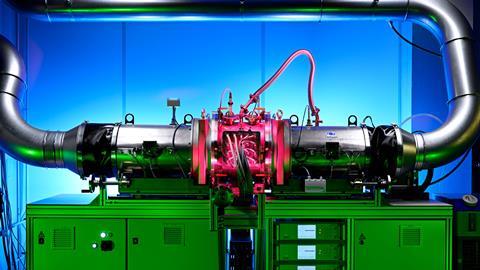

In a small room on the High Tech Campus in Eindhoven stands a prototype of a separation machine. The machine has one inlet and two outlets. It sucks in air from the outside, and the two outgoing streams are different in one very important respect: the concentration of carbon dioxide.

The machine is an invention of Carbyon, a start-up company that wants to extract CO2 from the air. At the heart of the invention is a sorbent that can bind CO2. You expose it to the air, then close the valves and heat the material, releasing the CO2 and increasing the concentration in the exhaust. If you can perform this adsorption and desorption step in a few seconds, you can efficiently process large volumes of air on an annual basis. Carbyon aims for an outlet with 60-70% CO2. Higher purity is too expensive and can be achieved with existing technologies. Eventually they want to build thousands of these machines.

The company was founded four years ago by ceo Hans de Neve. At the time, he was working at TNO on materials for solar panels, but also had a budget for Friday afternoon experiments. That’s when he got the idea to use the materials he was working with for direct air capture. The first experiments were promising enough for him to leave TNO and found Carbyon. In the end, the original material proved to be unsuitable and has since been replaced by a high-performing alternative: highly porous functionalised activated carbon. Carbyon is not disclosing further details at this time.

A huge challenge

‘If you look at the goals of the climate agreement, we have to become carbon negative’, says Arno van Hoof, who is responsible for the development of the chemical sorbent at Carbyon. After completing his PhD at Eindhoven University of Technology, he started in the analytical department of Shell. Working at Carbyon is the exact opposite. ‘Personally, I can learn a lot here and the goal appeals to me enormously. I want to leave the world in good shape for the next generation. We are facing a huge challenge and I can contribute more here than I could at Shell.’

According to Van Hoof, there are four applications for which they can sell their machines: greenhouse horticulture, underground CO2 storage, solar fuels and CO2 capture in materials. ‘Greenhouses now burn natural gas to increase the CO2 concentration in the greenhouse so that plants grow faster. You could replace that with one of our machines.’ For storage in materials, he thinks of cement and concrete production. He expects greenhouses and concrete storage to be the first customers. ‘In both cases, the CO2 does not need to be super-pure. In the case of catalysis, for the production of solar fuels, it has to be.’

When Van Hoof started two years ago, the search for the right material was still in full swing. ’It was a matter of not giving up, reading papers and trying a lot.’ The first prototype, which sucks in outside air and emits gas with a higher concentration of CO2, is now in place. Because they do not know exactly what is in the inflow, they can test how the machine works in a realistic environment. They are now dependent on the weather, and humidity in particular fluctuates enormously. They also want to estimate the cost per amount of CO2 processed. ’The aim of this prototype is to get a good estimate of the energy budget. Ultimately, we want to switch to renewable sources such as wind and solar power.’

’Everyone is here first and foremost for the fight against climate change.’

XPRIZE Milestone Award

Van Hoof stresses that Carbyon’s approach is not to make as much money as possible. ’To be sustainable as a company, you have to be able to make a profit at the end of the day, but everyone here is here first and foremost to fight climate change, and that is a good feeling. Our company is a success when the towers are in the field and we are carbon negative as a company.’ When Van Hoof started, there was one test bed, now there are four, with a fifth in the pipeline, and the workforce has grown from 10 to 30. ’It’s very cool to see that growth.’

Carbyon has raised €8 million in investment so far, including from InvestNL and the Brabant Enterprise Company. It also received $1 million from Elon Musk’s XPRIZE Milestone, a competition for projects that help remove CO2 from the atmosphere. ’This required a lot of documentation and we worked hard for it. To be rewarded for that was a great moment. It is a confirmation that we are on the right track.’

Nog geen opmerkingen