With a little tinkering with their DNA, we can make bacteria produce a variety of molecules. Even petrochemical molecules belong to the possibilities. Though there are still obstacles to overcome, bacteria could offer a route to a sustainable petrochemical industry.

In the pharmaceutical and food industries, micro-organisms are common production vehicles. Citric acid for soft drinks, lactic acid in cheese and yoghurt; all made by bacteria and fungi. But researchers are starting to gradually modify bacteria to produce a variety of completely different molecules. Molecules that we currently make from petroleum, such as ethyl acetate or isopropanol.

Are bacteria the key to a sustainable petrochemical industry? According to Ruud Weusthuis, professor of microbial biotechnology at Wageningen University, there are many opportunities to make petrochemicals more sustainable. Bacteria are certainly one of them. ‘Whichever way you look at it, we need to find more sustainable raw materials and production methods. And because bacteria can carry out so many different chemical reactions, they could play a role in this.’

‘Pushing bacteria in a certain direction remains a challenge’

Therefore, researchers worldwide are working on changing bacteria so that they can produce different types of molecules. ‘With the toolkit of molecular biology, we can specifically modify the DNA of micro-organisms’, Joost Teixeira de Mattos explains, who is emeritus professor of microbial physiology at the University of Amsterdam and co-founder of the biotech companies Photanol and Sustenso. ‘We can use, for example, CRISPR-Cas9 to incorporate certain genes or gene combinations that force the biochemical pathways in such an organism to our will.

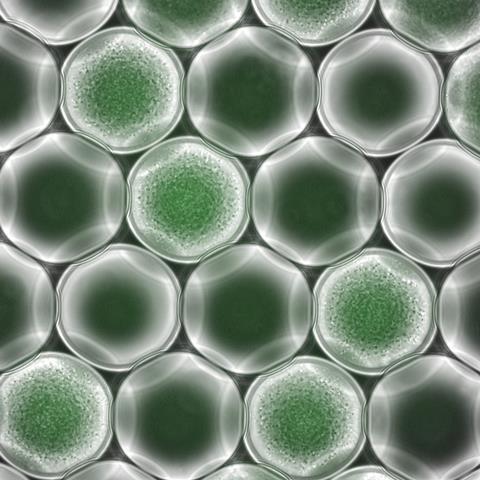

This requires knowledge of metabolism and a good understanding of the functions of different biochemical pathways. ‘You need that understanding to find leads’, Teixera de Mattos says. ‘You can force molecules in the bacteria to take a turn from a metabolic intermediate to a particular end product, but you need to know how this affects the metabolism and survival of the bacteria.’ Photanol works with cyanobacteria that, under the influence of light, convert CO2 into components they need for growing. ‘By incorporating genes, we make breakdowns from a central metabolite to a wide range of end products.’

Smart detection

In 2017, a PhD student from Weusthuis succeeded in adding the enzyme alkane hydroxylase to E. coli using a similar strategy, after which this bacterium was able to produce alkane diols. Recently, Weusthuis caused an E. coli bacterium to make ethyl acetate. This was not easy, as he first had to find an enzyme that can make ethyl acetate. ‘It has been known for a hundred years that yeast can produce this molecule, but how exactly was still unclear. After a long scavenger hunt, we found the responsible enzyme and it happened to work well in our bacteria.’ The new E. coli has an efficiency of about 70%. ‘Still far from optimal, but good enough for us to show the principle works’, Weusthuis says. ‘There is certainly still room for improvement, but this is a task more suitable for the industry.’

‘You have to find the balance between optimal production and survival of the bacteria’

Photanol and Weusthuis’ examples give the impression that it is not that complicated to bend a bacterium to your will. In practice however, it’s not that easy. Often, this is a process of many years, because it is quite a hassle just to find out exactly which mutations or added genes give the desired effect. Fortunately, researchers at KU Leuven are working on methods making the process a bit easier. ‘We are developing lab-on-a-chip systems to quickly and efficiently modify and optimise micro-organisms to produce the desired molecules, Jan Michiels explains, who is professor at the Centre for Microbial and Plant Genetics at KU Leuven and the VIB. ‘This system consists of a series of small droplets in which only one variant of your organisms grows. Using smart detection techniques, you can then determine which variants make the desired molecule.’

They have only been working on it for a year now, but they’ve already had reasonable success in making the droplets and keeping them separated from each other. For these tests, they are working with an industrial partner to produce three different molecules: alpha-keto-glutaric acid, amyl alcohol and fatty acids. ‘The advantage of these molecules is that you can detect them in the droplets using fluorescence’, Michiels says. ‘But in time, we want to make other molecules as well. As long as the basic system is up and running, it can certainly be interesting for the production of petrochemical molecules as well.’

Production vs. survival

Nonetheless, Michiels is under no illusion that this system solves all the problems of bacterial modification research. ‘It remains a challenge to push bacteria in a certain direction. They are living organisms that want to grow and can adapt to circumstances, so you can never one hundred percent predict what will happen. However, this is precisely what makes this work so interesting.’ And even if bacteria do manage to make the right molecules, success is not guaranteed. Toxicity is a major problem in these kind of processes, Teixeira de Mattos explains. ‘The bacteria can die from the molecule you are trying to make. So you will have to figure out what concentrations the organisms can handle, and then find a balance between the optimal production and survival of bacteria.’

On a small scale, in the laboratory, this balance is still present; upscaling often proves difficult, however. Especially since aspects such as contamination can start to play a bigger role. Weusthuis: ‘You do not want other bacteria in your reactor competing and eating raw material. That it simply more difficult to prevent on a large scale than in the lab.’ Sometimes the available technology is a challenge as well. ‘Cyanobacteria, for example, need to receive just enough light of a specific intensity to grow and this is not possible in a dark, sealed tank’, Teixeira de Mattos says. ‘So we need to develop new techniques for that.’

‘In the hydrogen economy, these organisms would fit very well’

Nevertheless, the researchers are convinced it should be possible in the long run. Teixeira de Mattos mentions other similar fields as examples. ‘Corbion creates lactic acid on a huge scale and notably all bio-ethanol in the world is made by bacteria. So it is definitely possible, it just takes time to find a balance and get everything right.’ And there are more encouraging practical examples.

At North-western University in the US, for example, professor Michael Jewett and his team already managed to produce several petrochemical molecules using bacteria. For this, they use Clostridium autoethanogenum, a special organism that can ferment gases. Recently, these researchers made two variants of C. autoethanogenum that can convert CO2 gas into acetone and isopropanol, respectively. Although the development of these variants is still in the lab phase, there are high hopes that it will also work on an industrial scale. Indeed, an earlier variant of this bacterium from Jewett’s lab has been used on an industrial scale since 2018. The bacterium converts emissions from a steel mill into approximately 90.000 tonnes of ethanol per year.

Fair settlement

Very promising, but can these organisms really compete with the current production of chemicals from oil in the end? That all depends on how the energy supply will develop, Weusthuis says. ‘We have high hopes for the hydrogen economy and these micro-organisms would fit in very well. We could let bacteria convert sustainably generated hydrogen gas together with CO2 from the air into chemicals we need. We are not there yet, but it could certainly be done in the future.’

Teixeira de Mattos believes the economic aspects especially to play a big role. ‘It all depends on what you include in the costs of a molecule. The petrochemical industry is relatively cheap now, but partly because prices do not take into account the environmental costs of such production. Once we start to fairly account for that, bacteria stand a good chance of becoming the more sustainable and cheaper alternative.’

Of course, we need enough bacteria to produce all these petrochemical molecules, but according to Michiels this is not a problem. ‘In recent years, we have seen that it is possible to get bacteria to produce a variety of molecules. The only question is how to make these organisms more efficient and how to scale up the processes. These challenges are not insurmountable, and we are happy to start working on this.’

Nog geen opmerkingen