Danish researchers have come up with a plan to produce and apply the jeans dye indigo in a much more sustainable way. It appears to be a viable method, they show in Nature Communications.

If any colour is iconic, it is that of jeans, derived from the molecule indigo. This is now widely produced using highly reducing and alkaline substances, which is not good for the health of workers or the environment. Katrine Qvortrup, Ditte Welner and their colleagues at the Technical University of Denmark thought that if they could make this huge industry sustainable, they could have a major positive impact on the world.

The Danes’ idea was to develop an enzymatic process that could work in the existing industry. In this way, no major changes would be required and the process could be implemented almost immediately. They chose an enzyme from Polygonum tinctorium, a plant in the knotweed family that produces indigo. They mutated this enzyme, PtUGT1, until it produced a more stable variant that was still as active as the original. It couples β-glucose to the hydroxyl group of indoxyl to form indican.

Analyses and calculations in the paper show that the production process is feasible: the reaction conditions are better and healthier, and the researchers do not expect to have to change the workplace or put jobs at risk. So, in terms of production, it is similar to conventional methods, the only drawbacks being that it uses more water and land and is slightly more expensive: $9.90 instead of $5.00 per kilogram.

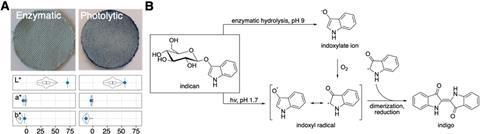

But it’s not all about production: the colouring of denim can also be improved. The researchers came up with two methods: enzymatic and photolytic dyeing. In almost every respect, both methods are better than conventional dyeing. Both in water and on land, the ecological impact is much lower and the toxicity to humans is also lower, especially with enzymatic dyeing.

Enzymatic dyeing involves the reaction of indican with a β-glycosidase, which cleaves the sugar molecule. The resulting indoxyl ion reacts with oxygen to form a radical and after dimerisation and reduction, indigo is formed. For photolytic staining, the jeans containing indican are soaked in an acidic solution (pH = 1.7) and exposed to light with a wavelength of 365 nanometres using an LED lamp. This energy causes the sugar molecule to split, leaving behind the indoxyl radical, after which you follow the same steps as above.

If these results were to be implemented immediately, the researchers estimate that global CO2 emissions could be reduced by 3.5 megatonnes and workers in denim factories would no longer be exposed to harmful substances. They believe the new process will be ecologically benign and economically competitive with the current one. Maybe we should change the name to denim green.

Bidart, G.N. et al. (2024) Nat. Commun. 15(1489), DOI: 10.1038/s41467-024-45749-3

Nog geen opmerkingen