Photocatalytic reactions are a hot topic at the moment, but the transition from laboratory scale to industrial scale remains a challenge. The PhotoScale consortium aims to design a photospinning disc reactor that will allow pharmaceutically interesting photocatalytic reactions to be carried out on a relatively large scale.

‘When photocatalysis emerged in the 1970s, it died a quiet death partly due to a lack of technological progress’, says Timothy Noël, professor of flow chemistry at the University of Amsterdam and one of the lead researchers of the PhotoScale consortium. He has recently noticed that photocatalysis is becoming a booming business. ‘The technology has come a long way since then. We are using this progress ourselves in the consortium, as we want to move to the production stage.’

PhotoScale consists of Janssen Pharmaceutica R&D, Signify (formerly Philiphs lighting) and the group of John van der Schaaf (Professor of Chemical Reactor Engineering at Eindhoven University of Technology) in addition to Noël’s group. This collaboration was fairly obvious, Noël says. ‘A few years ago, Koen Kuijpers was a PhD student in my group, working on the scale-up of photochemistry. During that project, we were already familiar with John van der Schaaf and Signify had reached out to us as well. Koen started working at Janssen after his PhD; so it was a no-brainer to start this collaboration.’ Especially since Janssen has a great interest in this topic.

Pharma-flavored

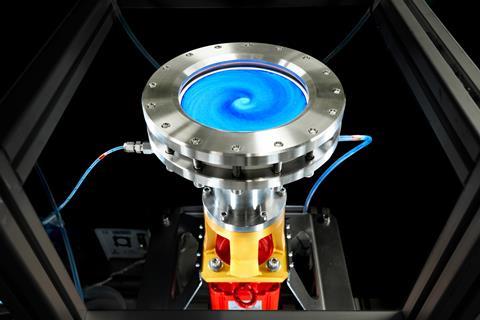

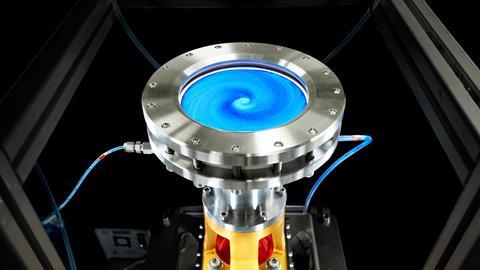

Funding for the project (€1.2 million) was provided by the NWO Open Technology Program. With this, PhotoScale aims to build a photospinning disc reactor capable of producing more than 20 kg of pharmaceuticals per day. Koen Kuijpers is working on this project as a Scientist Process Engineering at Janssen. ‘We already have a concept reactor and a light source, so we can start testing the chemistry with our reactor’, he says. ‘We have chosen certain model reactions to reduce raw material costs, since the reactor has a high throughput and uses a lot of materials. However, these model reactions are relevant for pharmaceuticals.’ Noël adds: ‘We know the “flavor” of pharma, for example sp2-sp3 cross coupling reactions. And we also try to select the cheapest catalysts as possible.’

Even though a well-thought out plan is in place, it is not an easy task. ‘There are still some questions and challenges present’, Noël explains. ‘How do we make this reactor safe and efficient to produce our target amount? Does it make sense to create a playbook for the users? And how does the chemistry react to very intense light sources?’ Kuijpers adds: ‘We still need to perform a lot of characterization: what effects do the parameters such as flowrates and temperature management have on the reactor? There is still much work left to do. We need to make a protocol to test all the parameters efficiently. Because of the high throughput, we have to be smart about how we analyze the data.

Stir bars

Yet the researchers are very confident in their plans. ‘Photospinning disc reactors have major advantages over the standard reactors used today’, says Kuijpers. ‘They can handle all multiphase reactions: gas-liquid, liquid-solid and gas-liquid-solid reactions are all possible in one system, because we are able to take the pressure decrease into account. You can compare it with the use of a stir bar, Noël says. ‘You add your liquid to a spinning reactor, similar as in the lab.’ And because the light shines on a relatively flat entity, you have an optimal photon transfer. ‘It is actually a mix between a plug flow reactor and a continuous stirred-tank reactor, so your reagents have a good residence time distribution’, Noël explained.

If the project succeeds, the consortium does not plan to block it off to others. ‘We have a mission to start a revolution in pharma’, Noël explains. ‘Money is less important. If you seal it up with patents you have a chance that nobody will use your invention, or that it will be circumvented. It is then best to sell it as a service with the necessary know-how.’ ‘The value’s in the molecules, not in the technology’, Kuipers adds. ‘You have an obligation to patients, it would be a shame to withhold a valuable technique from other companies.’ Noël thinks they might start a start-up based on the ideas. ‘So there is expertise to support others. Fortunately, all parties get along well, so I have good faith that they are going to be fine.’

Kuijpers also shares his gratitude for the NWO’s Open Technology Program. ‘The final step to practice is difficult to make at an university’, he says. ‘We are reaching this point, we are no longer solely performing fundamental chemistry but are carrying out applied chemistry as well. We are therefore glad that NWO pays attention to these kinds of projects.’ Noël agrees. ‘It is our duty to do something valuable with the tax money. I notice that more people around me want to follow the transition. And that’s a good thing: we should not get stuck at the milligram scale.’

Nog geen opmerkingen